Disk Permanent Magnet Governor

The Disk Permanent Magnet Governor is a pivotal component in a wide array of mechanical systems, most notably in engines and heavy machinery. It adeptly regulates and ensures a steady rotational speed. Leveraging the enduring properties of permanent magnets and the foundational principles of electromagnetism, this innovative device masterfully controls the velocity of rotating parts. In doing so, it guarantees that operations are not only stable but also run with optimal efficiency.

EMWorks for Inventor Solution

EMWorks for Inventor elevates the design and analysis of permanent magnet devices with its sophisticated 3D electromagnetic simulation capabilities. This advanced FEA software solution, enriched with multiphysics functionalities, streamlines the process of modeling, analyzing, and optimizing, offering an unparalleled toolset for precision engineering in the realm of electromagnetics.

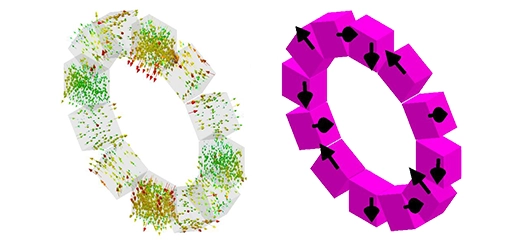

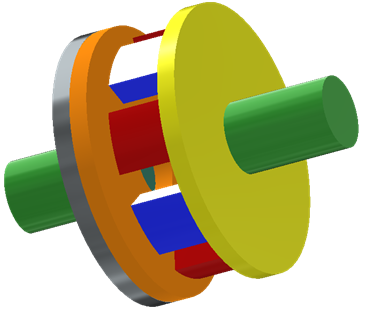

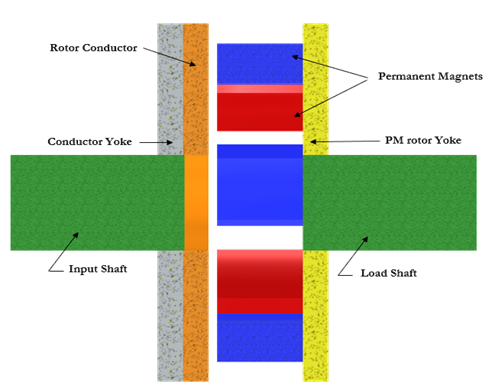

The governing mechanism, illustrated in Figures 1 and 2, primarily features a rotating disk affixed to the shaft whose speed is to be regulated. Embedded within this disk are permanent magnets, strategically positioned according to a specific layout. As the shaft turns, these magnets engage in dynamic interactions with adjacent magnetic elements, effectively modulating the rotational speed.

Design Optimization of the Disk

Optimizing the design of Disk Permanent Magnet Governors is pivotal for enhancing their performance across several parameters, including efficiency, precision in speed regulation, reliability, and cost-effectiveness. The optimization process involves meticulous adjustments to the governor's structure, focusing on the following critical elements:

-

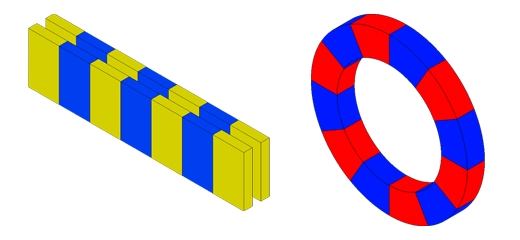

Magnet Configuration: The strategic placement and selection of permanent magnets on the disk are fundamental. By fine-tuning the arrangement and quantity of magnets, engineers can achieve optimal magnetic field strength and distribution, enabling accurate control mechanisms.

-

Air-Gap Dynamics: The air-gap, or the space between the disk's permanent magnets and the conductive rotor, plays a significant role in the system's performance. Modifying this gap alters the magnetic field's intensity and the system's responsiveness. The air-gap directly impacts the torque produced by the governor, affecting its operational efficiency.

-

Disk Material and Geometry: The choice of material for the disk, particularly materials with high electrical conductivity, is crucial in maximizing eddy current generation. Furthermore, refining the disk's geometry can significantly enhance the interaction between the magnetic field and these eddy currents, leading to improved braking efficiency and overall system performance.

Through these design considerations, the aim is to develop a Disk Permanent Magnet Governor that not only meets but exceeds the required performance standards, ensuring a blend of efficiency, accuracy, and cost-effectiveness.

Magnetostatic analysis

Magnetostatic analysis within EMWorks for Inventor offers a sophisticated tool for exploring and comprehending the behavior of magnetic fields in engineering devices and systems when they are in a static or steady-state condition. This approach yields critical insights into how magnetic flux is distributed, the intensity of magnetic fields, and related effects within a system.

Key outputs from magnetostatic analysis encompass a range of important parameters, including:

-

Force and Torque: Evaluating the mechanical forces and rotational moments acting within the system.

-

Inductance: Determining the system's ability to store magnetic energy in a magnetic field.

-

Resistance: Assessing the opposition to the flow of current within the system.

-

Flux Linkage: Understanding the total magnetic flux interacting with a closed loop or circuit.

-

Magnetic Field Energy: Calculating the energy stored in the magnetic field of the system.

-

Current Distribution: Analyzing how electrical current flows through the system's components.

-

Temperature Distribution: Mapping out the variation of temperature within the system, which can affect its magnetic properties.

By providing these detailed outputs, magnetostatic analysis via EMWorks for Inventor empowers engineers and designers to deeply understand magnetic interactions and optimize the design and performance of their engineering systems and devices.

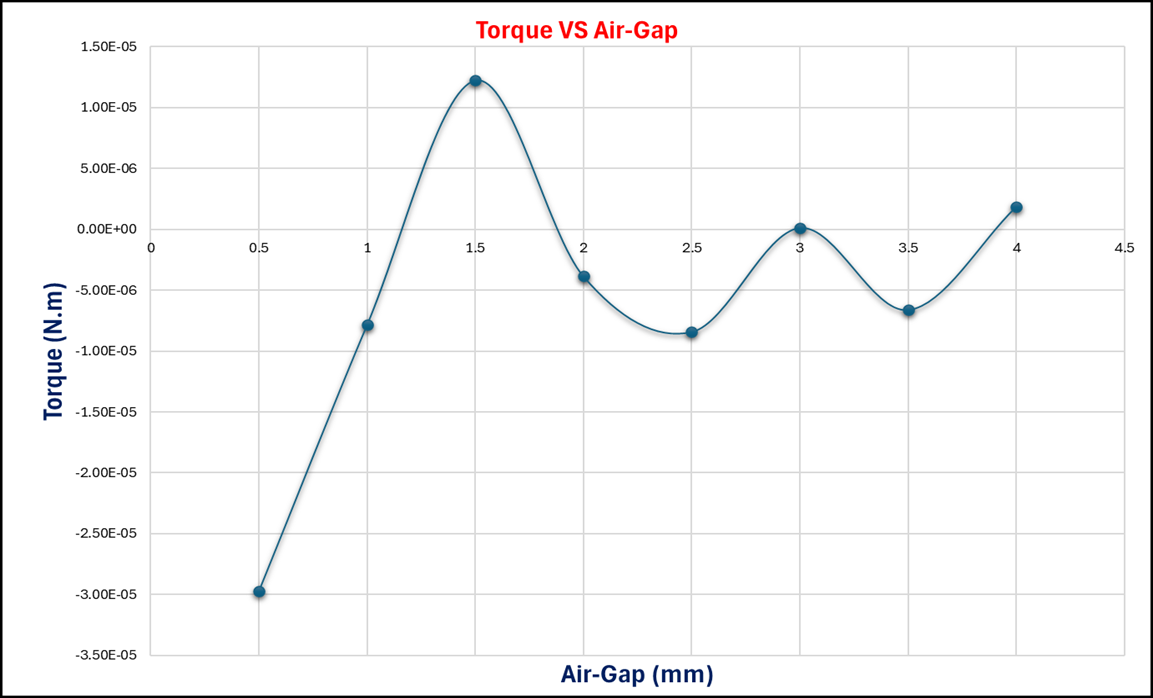

Torque vs Air-Gap

Optimizing the air-gap size is paramount for enhancing torque output, ensuring both efficient and reliable performance across diverse operational conditions. Figure 3 illustrates the relationship between torque behavior and variations in air-gap size, highlighting the critical balance needed to achieve optimal system performance.

Figure 3: Torque vs Air-gap

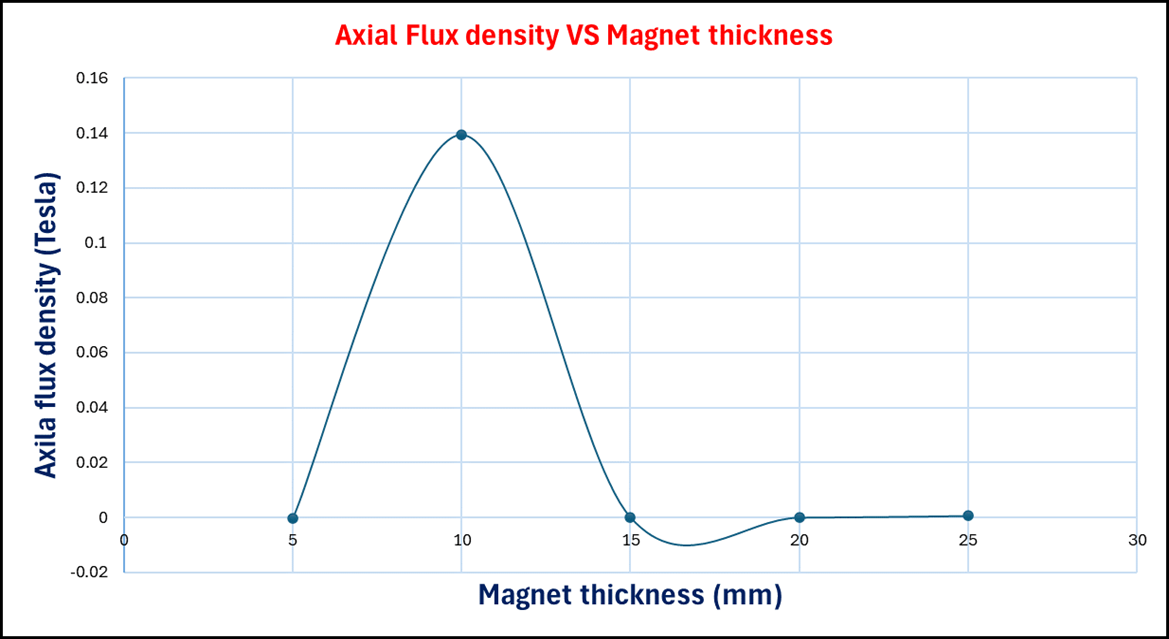

Axial Flux vs Magnet Thickness

The performance of axial flux machines is significantly influenced by the thickness of the magnets used within them. Grasping the dynamics of how magnet thickness affects axial flux is essential for fine-tuning the design of these machines, particularly when tailoring them to specific applications. Figure 4 elucidates the relationship between axial flux behavior and variations in magnet thickness, showcasing the critical insights needed for design optimization.

Figure 4: Axial Flux vs magnet thickness

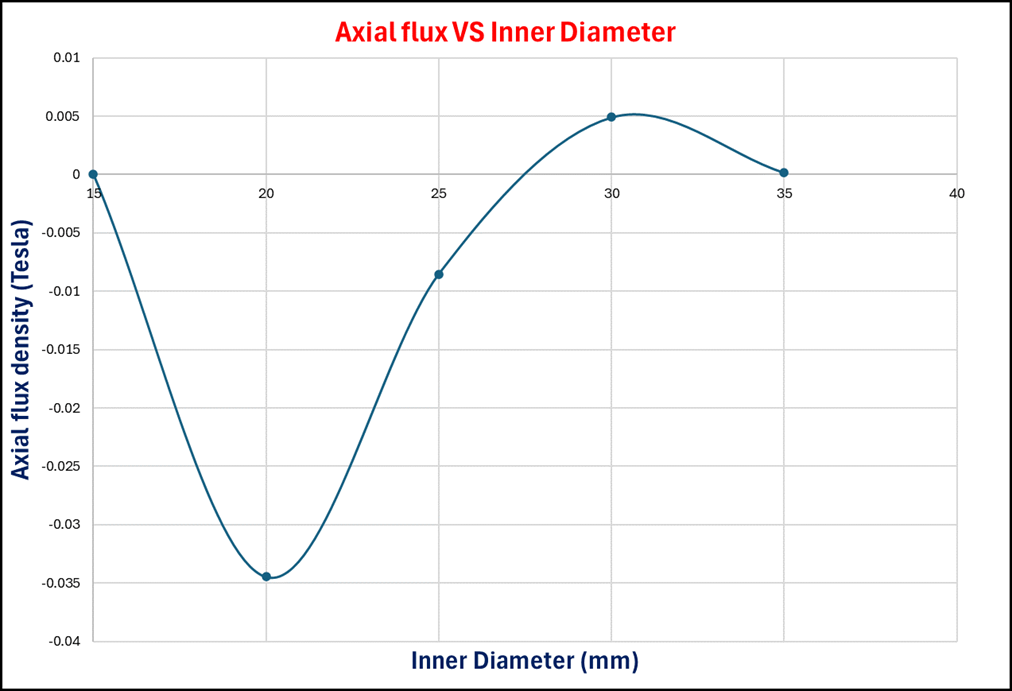

Axial Flux vs Inner Diameter

The inner diameter of the magnets plays a pivotal role in dictating the magnetic flux density distribution across the air gap. Generally, a larger inner diameter fosters a more even distribution of flux density, enhancing the uniformity across the gap. Conversely, a smaller inner diameter tends to create steeper flux density gradients, concentrating the magnetic field more intensely in specific areas. Figure 5 graphically represents the behavior of axial air-gap flux as it correlates with changes in the magnet's inner diameter, illustrating the impact of these diameter variations on the magnetic flux density distribution.

Figure 5: Axial flux vs inner diameter

Magnetic Flux Distribution inside the Conductor

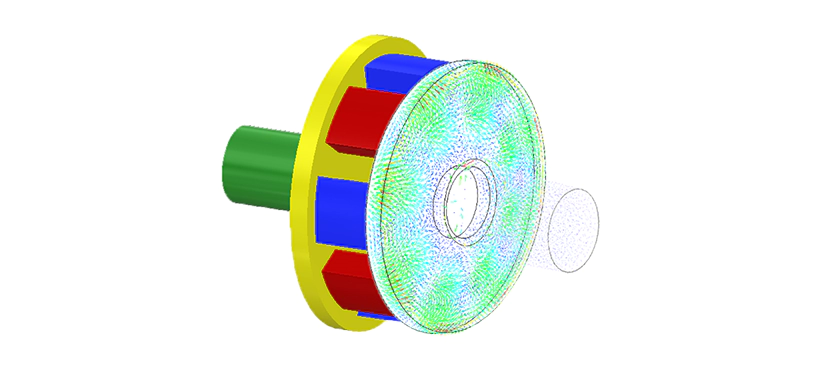

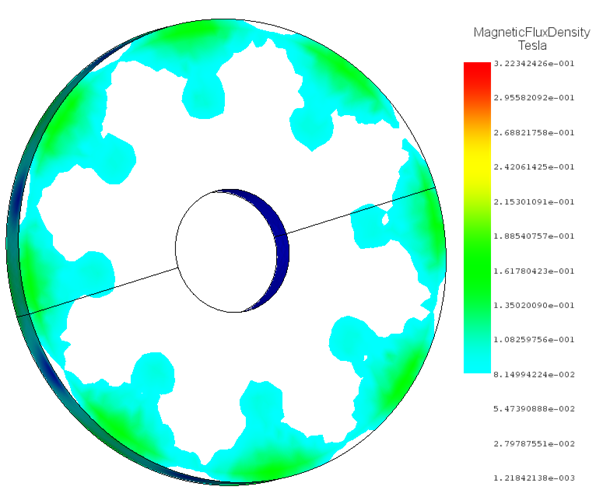

The intricacies of magnetic flux distribution within a conductor are governed by a confluence of factors, including the conductor's material properties, the pattern of current flow, its geometric characteristics, and external environmental influences. EMWorks for Inventor is adeptly designed to model and analyze these complex interactions, providing a precise representation of how the magnetic field behaves inside conductors. This capability is visually demonstrated in Figure 6, which offers a detailed view of the magnetic flux distribution, highlighting the tool's effectiveness in capturing the nuanced effects of various factors on the magnetic landscape within a conductor.

Figure 6: Magnetic flux density inside the conductor

Transient Magnetic Analysis

Transient Magnetic analysis in EMWorks for Inventor empowers engineers to delve into the dynamic behaviors and time-dependent phenomena within the governor model. This sophisticated analysis tool is capable of accurately simulating time-varying magnetic fields, which is essential for examining complex phenomena such as magnetic hysteresis, eddy currents, and electromagnetic transients in intricate governor models.

The analysis yields a variety of critical outputs that provide insights into the temporal evolution of the system, including:

- Time-dependent distributions of magnetic flux density and magnetic field strength, offering a snapshot of how these properties fluctuate over time.

- Time-Dependent Forces that act on different parts of the governor, affecting its mechanical response and performance.

- Transient Torque, highlighting the variations in rotational force that can impact the governor's operational efficiency.

- Eddy Currents and Losses, providing an understanding of the currents induced by changing magnetic fields and their associated energy losses.

- Induced Voltage, which is crucial for assessing electromagnetic induction effects within the system.

- Flux Linkage & Inductance, offering insights into how magnetic flux interacts with the electrical circuitry of the governor.

- Magnetic Field Energy, tracking the energy stored in the magnetic field over time.

By leveraging Transient Magnetic analysis, engineers can gain a comprehensive understanding of the dynamic interactions within the governor model, enabling the optimization of its design and functionality for enhanced performance across a wide range of operating conditions.

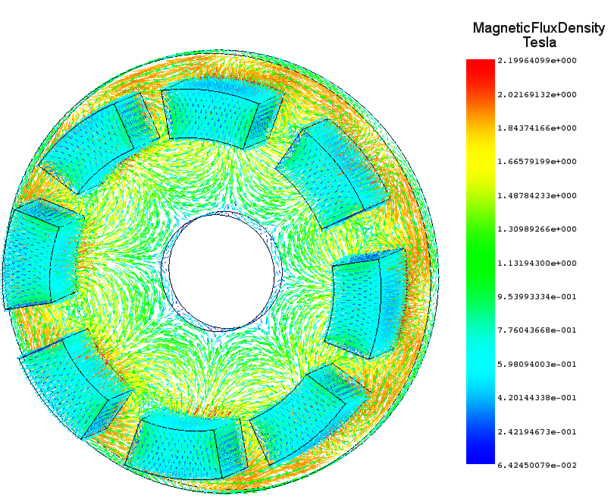

Transient Magnetic Flux Distribution inside PM & PM Disk

Transient magnetic analysis in EMWorks for Inventor plays a crucial role in visualizing the temporal evolution of magnetic fields. This analysis provides a clear picture of how magnetic fields change over time, which is vital for optimizing the design and functionality of magnetic devices. Figure 7 illustrates the spatial distribution of magnetic flux density within the permanent magnet and the disk.

Figure 7: Transient Magnetic Field Distribution inside PM & PM Disk

Current Density Distribution inside the Conductor

Analyzing the distribution of current density is pivotal for comprehending the dynamics of how electrical current traverses a conductor. This understanding is influenced by factors such as the conductor's geometry, the properties of the material it is made from, and the boundary conditions imposed upon it. Identifying regions of high current density is critical, as these areas can indicate potential hotspots or inefficiencies within the system. Similarly, recognizing where current is either concentrated or dispersed helps in assessing the overall electrical performance and safety of the conductor. The animation depicted in Figure 8 serves as a visual tool, enabling engineers to easily spot these significant regions. Through such detailed visualization, it becomes possible to optimize the conductor's design to ensure a more efficient and safe current flow, tailored to specific application requirements.

Figure 8: Current Density Distribution inside the Conductor

Heat Flux Distribution inside the Conductor

EMWorks Inventor's thermal analysis feature is instrumental in simulating heat flux distribution, offering invaluable insights into the thermal behavior of electrical systems under diverse operating conditions. This type of analysis is crucial for the design and optimization process of electrical systems, aiming to ensure their operation is both safe and efficient. By accurately modeling how heat is generated, distributed, and dissipated within these systems, engineers can identify potential overheating issues, assess the effectiveness of cooling strategies, and predict the system's performance in real-world scenarios. Figure 9 provides a visual representation of heat flux distribution, aiding in the understanding and improvement of thermal management practices within electrical systems, thereby contributing to their overall reliability and safety.

Figure 9: Heat Flux Distribution inside the Conductor

Conclusion

In this application note, we've highlighted the Disk Permanent Magnet Governor's crucial role in mechanical systems and how EMWorks for Inventor enhances its design and optimization through advanced electromagnetic simulation. Our analysis across magnet configurations, air-gap dynamics, and thermal behavior underscores EMWorks' value in elevating governor performance. By enabling precise design adjustments and offering deep insights into electromagnetic and thermal phenomena, EMWorks for Inventor ensures these governors achieve unparalleled efficiency, reliability, and cost-effectiveness, marking a significant leap forward in electromagnetic device engineering.

References

[1] Manman Xu, Yili Fu, Long Shao, Xiangdong Wang,Yimin Lu & Chuqing Cao, Optimized design of permanent magnet for disk permanent magnet governor[2] Lei Wang, Zhenyuan Jia, Li Zhang, Investigation on the accurate calculation of the temperature ?eld of permanent magnet governor and the optimization method of heat conduction