Inductance Calculation in Induction Cooker Coils

Induction Heating

Induction heating warms conductors like metals through electromagnetic induction, where a coil carrying high-frequency AC-current induces eddy currents, generating heat. This process, known as the Joule effect, hinges on the principle that greater resistance in the conductor leads to more heating, showcasing the efficiency and precision of this modern heating method.

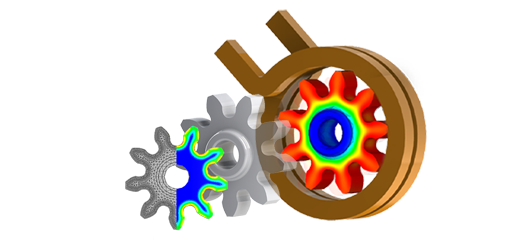

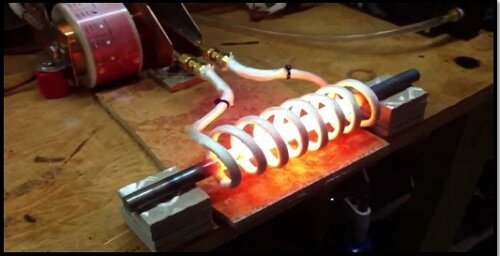

Figure 1- A conducting rod is heated using induction

Induction heating generates internal heat without contact, enabling rapid warming in applications like furnaces, welding, and cooking appliances.

What is induction cooking?

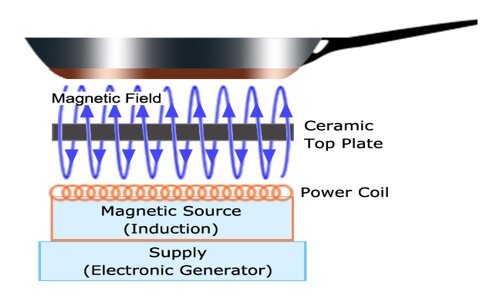

Induction cookers heat ferromagnetic vessels directly via a copper coil, unlike traditional flame or electric coil methods, for swift temperature rise, separated by a ceramic layer.

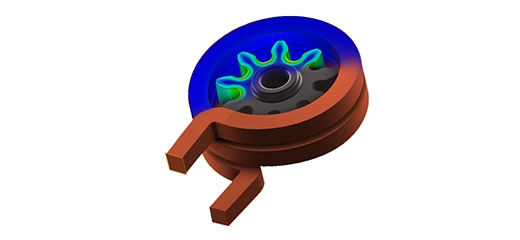

Figure 2 - Elements of induction cooking appliance

High-frequency AC in a copper coil creates eddy currents in cookware, rapidly generating heat. For optimal cooking, ferromagnetic materials like cast iron or select stainless steels are recommended over aluminum or copper, unless modified with a ferromagnetic disk. Ferromagnetic cookware offers greater heat production due to higher electrical resistance and more efficient joule heating from lower skin depth.

Why induction induction-based cooking attractive?

Induction cooking is more energy-efficient and faster, offering consistent, high thermal efficiency. A 2001 U.S. Department of Energy report highlights an 84% energy transfer efficiency for induction cooktops, compared to 74% for smooth-top electric units. Its heating performance rivals that of gas burners, with a control system that ensures energy is not wasted if the cookware is absent or too small. Additionally, the flat cooking surface makes it easy to clean and maintain, as it remains cool enough to prevent food from burning and sticking, with heat generated directly in the vessel.

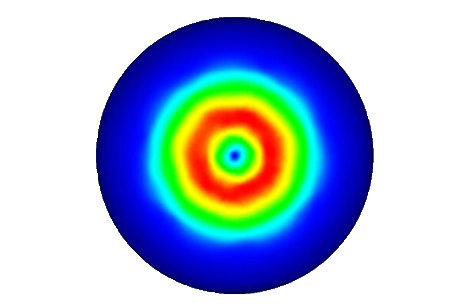

Figure 3 - Heat is produced only in the vessel and not in the top plate

Simulation using a standard induction cooker coil arrangement

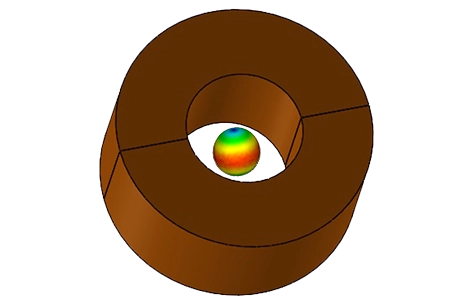

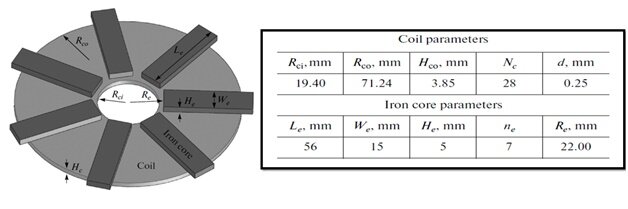

Figure 4 displays a CAD model of a coil and iron core setup for induction cooking, simulated using EMS at 24 KHz AC excitation. The simulation calculated the coil's inductance and visualized the magnetic flux density, demonstrating the model's effectiveness for induction cooking technology.

Figure 4 - CAD model of a typical coil using for induction cooking

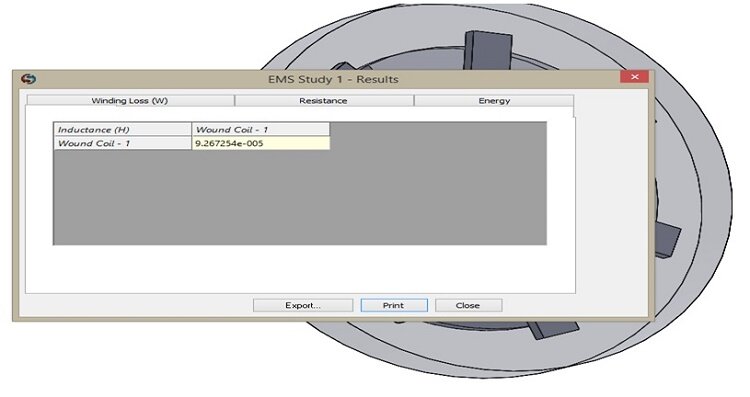

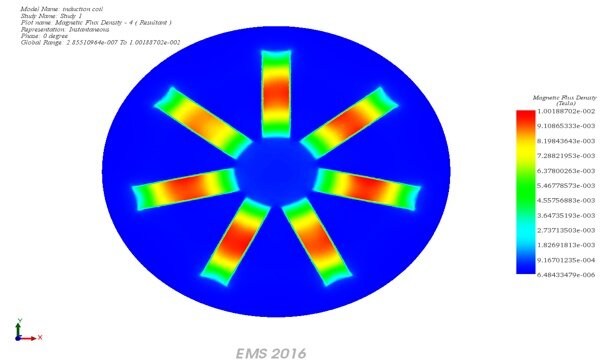

The software-calculated inductance of 92.67 micro Henry closely matched the laboratory result of 93.8 micro Henry. Figure 5 illustrates the magnetic flux density distribution within the coil and iron cores, showcasing the precision of the simulation

Figure 5 - The plot of magnetic flux density in the coil and the iron cores

Conclusion

Induction heating represents a significant advancement in modern heating methods, using electromagnetic induction to warm conductors like metals efficiently and precisely. This process relies on the Joule effect, where high-frequency AC currents in a coil induce eddy currents in the material, generating heat without direct contact. This method is highly efficient, especially for applications requiring rapid and uniform heating, such as furnaces, welding, and notably, cooking appliances.

Induction cooking, a prime application of this technology, heats ferromagnetic vessels directly through a copper coil, offering a swift temperature rise and higher energy efficiency compared to traditional cooking methods. With an 84% energy transfer efficiency, induction cooktops surpass the efficiency of smooth-top electric units and rival gas burners in heating performance. The technology's appeal also lies in its safety and convenience, featuring a cool-to-touch cooking surface that prevents food from burning and sticking, facilitating easy cleaning and maintenance.

A simulation using EMS at 24 kHz AC excitation of a standard induction cooker coil arrangement further validates the effectiveness of induction cooking. It accurately calculates the coil's inductance and visualizes the magnetic flux density, demonstrating the precision and reliability of using such simulations in designing induction cooking technology. This approach not only confirms the theoretical advantages of induction cooking but also highlights its practical applications in creating efficient, safe, and environmentally friendly cooking solutions.