What is a RADAX Motor?

A RADAX motor is a hybrid combined radial-axial (RADAX) flux motor. It combines a radial flux motor with one or more axial flux motors, within the same motor housing. It has been reported to have several advantages, including higher torque, a higher back EMF, compact size, and suitable for direct drive systems. The RADAX technology is recommended for applications that require high volume density and for vehicles spending a substantial amount of time idling or other low-speed actions. Nevertheless, nature does not have a “free lunch”. That is, a RADAX motor suffers from high axial force acting on the axial rotors as well as high initial cogging torque.

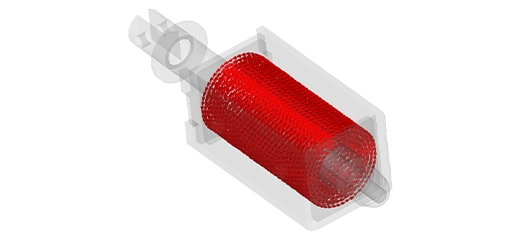

Fig. 1. An Exploded View of a SolidWorks Model of a RADAX Motor

Fig. 2. A 3D View of a SolidWorks Model of a RADAX Motor

EMS Simulation of a RADAX Motor

To contribute to the understanding of this novel and promising technology, we used our virtual prototyping design motor software, EMS, to study and simulate a RADAX flux motor, shown above. To calculate the back EMF and the cogging torque, a no-load analysis is carried out. Below are some of the EMS no-load results:

Fig. 3. Fringe Plot of the Magnetic Flux Density in the Entire Model

Fig. 4. Fringe Plot of the Magnetic Field in the Stator and Surrounding Permanent Magnets

Fig. 5. The Temperature Distribution in the Stator Core

Fig. 6. The Back EMF Comparing the Radial, Axial, and RADAX Motors

Fig. 7. The Load Torque for the Three Configurations

Clearly, the RADAX motor produces a much higher back EMF compared to radial and axial configurations. As a matter of fact, the back EMF of the RADAX is almost the sum of both radial and axial combined. Similarly, the load torque is much higher for the RADAX configuration. Nonetheless, the impressive back EMF and load torque come with a price tag shown in the figures below.

Fig. 8. Comparison of the Axial Force Acting on the Axial External Rotors

Fig.9. Comparison of the Maximum Cogging Torque

Obviously, the axial force and cogging torque are much higher for the novel RADAX design which is problematic; the high axial force may cause deformation or even the braking of the rotors altogether; the high cogging torque is notorious for causing ripples and vibration.

Takeaways

The RADAX motor, blending radial and axial flux designs, offers impressive performance gains in back EMF and load torque. However, challenges like high axial force and cogging torque require resolution for practicality. Further research is essential to address these issues and unlock the full potential of RADAX technology. EMS software plays a vital role in this endeavor, facilitating analysis and guiding efforts to overcome RADAX motor limitations and advance its development.