Typical braking systems, i.e.hydraulic, pneumatic, mechanic, employed in most vehicles are designed to slow or halt the motion by converting kinematic energy into heat by friction. This type of brakes suffers from several drawbacks including overheating, wheel damage, boiling or leaking of the brake fluid, low air pressure in pneumatic brake, and regular maintenance. On the other hand, eddy current, or electromagnetic, braking systems, which are based on Faraday’s law of induction, are contactless; these brakes have several advantages including wear-free, frictionless, less noise, low maintenance, protection from overheating, safety, and high efficiency in high-speed situations. They are used in many applications like traditional and maglev trains, automotive and heavy engines, roller coasters, gym and rowing machines, robotic and medical equipment, and wind turbines. However, eddy current brakes have some drawbacks such as low torque at low speed, and no ability to hold the moving load at stationary position.

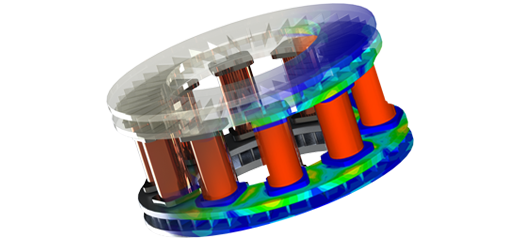

In this webinar, we shall explain to you eddy current braking system principles; discuss its major design challenges; then offer you some solutions using our electromechanical virtual prototyping software package, EMS. We shall address various multi-physics aspects related to this topic including motion, magnetic, structural, and thermal.