Power cables, such as the ones used in subsea oil field operations and offshore wind farms, transmit and carry megawatts of power to a variety of indispensable electromechanical systems such as pumps and motors. These massive cables lie on or under the seabed to transfer energy to the land. These cables are designed to operate in dynamic submarine environments for many years and they are very costly to prototype. They must be carefully designed to meet the required specifications and virtually tested using accurate and realistic physics-based simulations that take into consideration all what-if scenarios. In other words, shift to a zero-prototyping approach.

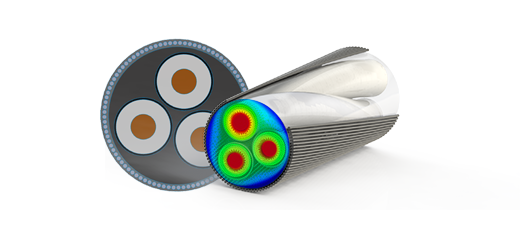

In this webinar, using EMS and EMWorks 2D simulations, we shall show you how to shift to a zero-prototyping approach and demonstrate it on a three-cores armored XLPE submarine cable. Special emphasis will be placed on the following calculations:

- Compute Capacitive, inductive, and resistive properties of the cable.

- Calculate and visualize magnetic and electric field distributions.

- Investigate skin and proximity effects.

- Estimate the electromagnetic losses.

- Explore twisting effects on the cable operation.

- Investigate the thermal aspects of the cable.