Magnetic Gear Simulation

Design and optimize contactless magnetic gearboxes for efficient torque transmission.

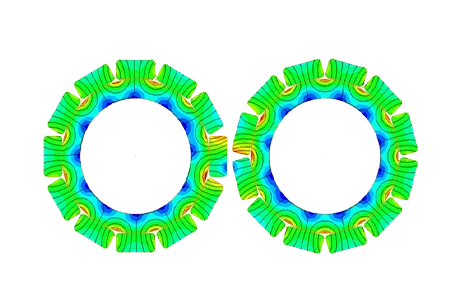

This application note uses EMWorks 2D finite element simulation to analyze coaxial magnetic gears, comparing torque, flux distribution, and gear ratio for two topologies and showing how magnetic gearing can reduce ripple and enable frictionless torque transmission.

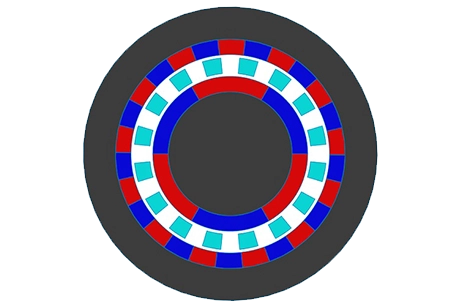

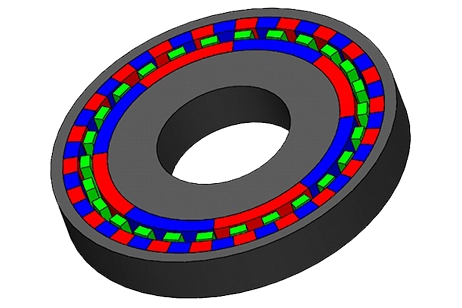

This note analyzes a coaxial magnetic gear with a 5.5 gear ratio using 2D and 3D finite element models. The study evaluates flux density in the air gap, torque on inner and outer rotors, and consistency between 2D and 3D results to validate the gear topology and operating principle.

This application note analyzes two parallel-axis magnetic gear topologies using 2D finite element simulation: a gear with radial permanent magnets and a gear with rectangular (parallelepiped) magnets. The study evaluates magnetic flux distribution and transmitted torque as functions of rotor angle, airgap length and number of pole pairs. Results show how partial pole overlap, airgap increase and pole-pair count influence torque amplitude and ripple, providing quantitative guidance for sizing magnetic gears for contactless torque transmission.