Understanding RF Heating in Food Processing

Radio Frequency Heating

RF heating, also known as Capacitive Dielectric Heating, offers rapid and uniform heating, making it ideal for various food applications like baking, drying, thawing, pasteurization, and sterilization. In this conventional process, food is placed between parallel electrodes emitting electromagnetic waves at frequencies of 13.56MHz, 27.12MHz, or 40.68MHz, chosen for their suitability by the US National Telecommunications and Information Administration. The alternating electric field induces molecular oscillation and friction, generating heat within the dielectric material. FEM analysis using HFWorks simulates RF heating in a 6 kW parallel plates RF system at 27.12MHz, aiming to quantify the impact of dielectric properties on food heating efficiency.

![a)-Effect of electrodes polarity on the Molecules polarity [2] b)- Schematic illustration of the RF heating process [3]](/ckfinder/userfiles/images/a%29-Effect-of-electrodes-polarity-on-the-Molecules-polarity-%5B2%5Db%29-Schematic-illustration-of-the-RF-heating-process-%5B3%5D.jpg)

Problem description

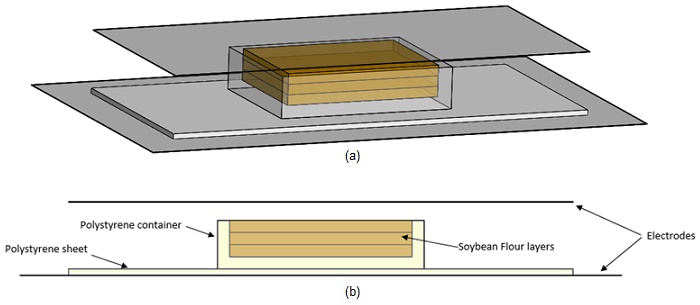

The model under study comprises an RF cavity chamber bounded by two parallel aluminum electrodes. A polystyrene sheet is positioned on the bottom electrode, supporting a polystyrene container containing three layers of soybean flour for RF heating. An S-Parameters study using HFWorks coupled with the thermal solver will predict the electric field intensity and temperature distribution within the soybean flour material. Detailed dimensions are provided in Table 1 for reference.

| Part | Dimension (mm) | ||

| Top Electrode | Width:400 | Depth:830 | Height:1 |

| Bottom Electrode | Width:590 | Depth:990 | Height:1 |

| Polystyrene container | Width:260 | Depth:340 | Height:80 |

| Polystyrene sheet | Width:400 | Depth:830 | Height:10 |

| Soybean flour layers | Width:220 | Depth:300 | Height:60 |

| Air gap | 30 | ||

| Material | Relative permittivity | Dielectric loss tangent | Thermal conductivity (W/m. K) |

| Soybean Flour | 3.96 | 0.38 | 0.097 |

| Polystyrene | 2.6 | 0.0003 | 0.036 |

| Aluminum | 1 | 0 | 160 |

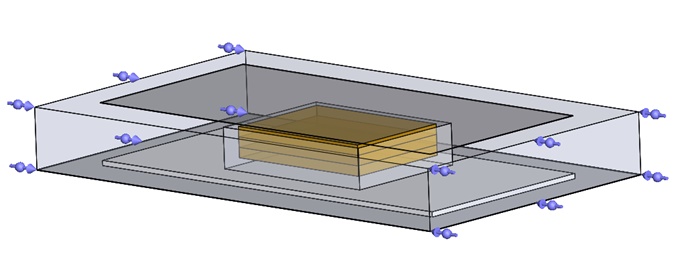

Electromagnetic boundary conditions

Wave Port: Applied to both entry and exit waveguide faces, receiving 6 kW of microwave power at 27.12 MHz.

Perfect Electric Conductor (PEC): Applied to the top and bottom faces of the waveguide box.

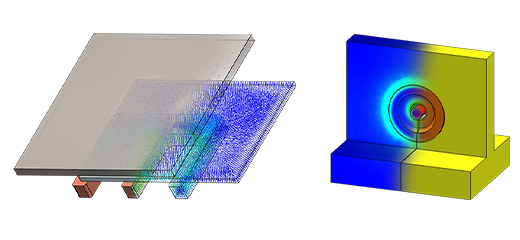

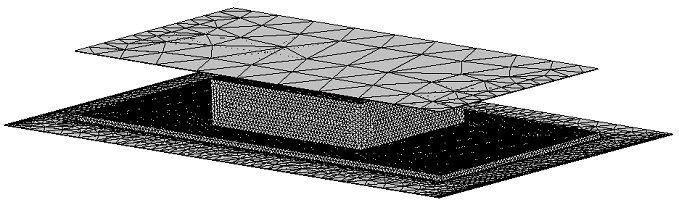

Mesh

A fine mesh control is essential for the dielectric parts to be heated accurately, ensuring precise results. The fully meshed model is depicted in the following figure.

Results

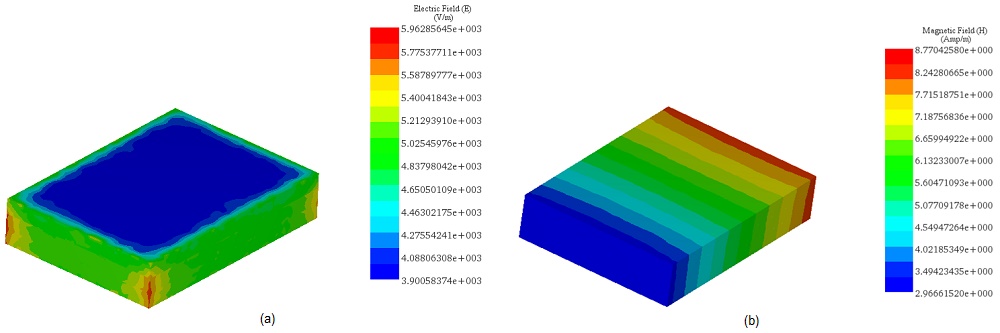

The HFWorks simulation yielded the following results: the first figure displays fringe plot results illustrating the distribution of electric and magnetic fields across the food layers under an excitation power of 6 kW. High electric field concentrations are observed at the corners and edges due to field reflection and refraction in these areas.

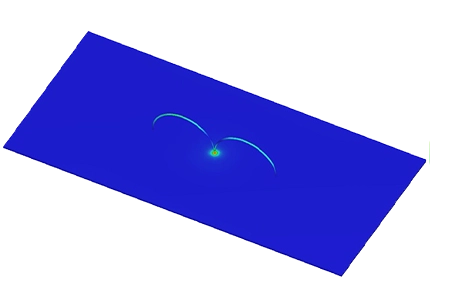

The following GIF animation illustrates the alternating electric field behavior between the top and bottom electrodes, resulting from the rapid change of polarity as detailed in the introduction.

The next table summarizes the dielectric loss quantity for each food layer for an excitation power of 6kW.

| Soybean Flour layer | Top layer | Middle layer | Bottom layer |

| Dielectric loss (Watt) | 27.79 | 30.73 | 31.13 |

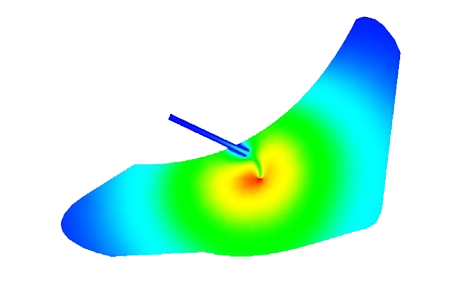

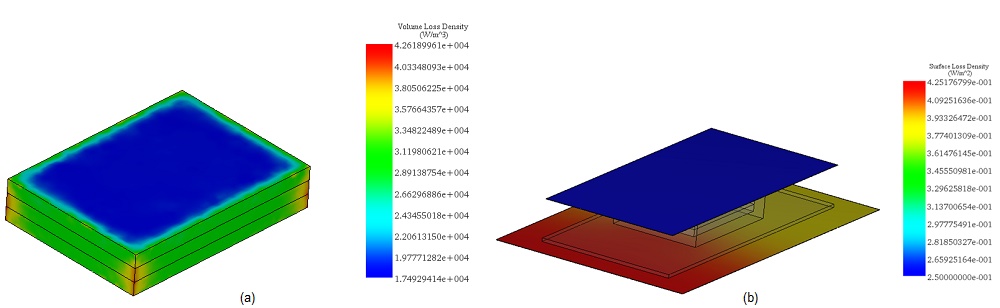

The subsequent figures depict the dielectric and conductor loss densities across the flour sample and the metallic electrodes. The initial figure confirms that the maximum volume loss density correlates with the electric field intensity, concentrated at the corners and side walls in contact with the container. Negligible conductor losses are observed compared to the dielectric losses for the applied excitation power.

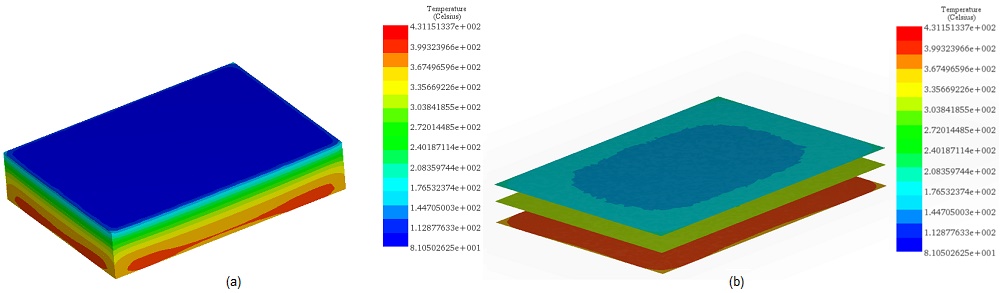

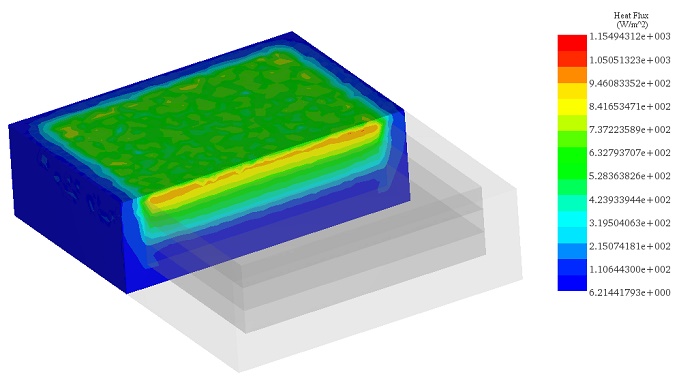

In the thermal analysis, a convection boundary condition is set for the upper surface of the sample, with an ambient temperature of 20°C and a convection coefficient of 20 W/m^2·°C. The resulting spatial temperature profile of the soybean across the three layers is illustrated below: reaching a peak steady-state temperature of 431°C at the bottom layer, directly in contact with the polystyrene container.

Conclusion

This application note explores the utilization of Radio Frequency (RF) heating, specifically Capacitive Dielectric Heating, for food processing applications such as baking, drying, thawing, pasteurization, and sterilization. Focusing on a 6 kW parallel plate RF system operating at 27.12MHz, the study employs FEM analysis through HFWorks to evaluate the impact of dielectric properties on the heating efficiency of soybean flour. The RF heating process involves placing food between parallel electrodes, where electromagnetic waves induce molecular oscillation and friction, generating heat within the material. The simulation predicts electric field intensity and temperature distribution, revealing high electric field concentrations at the corners and edges due to field reflection and refraction. Dielectric losses are quantified for each layer of soybean flour, with the bottom layer experiencing the highest dielectric loss and reaching a peak temperature of 431°C. The study underscores RF heating's capability for rapid and uniform thermal processing in the food industry, supported by detailed electromagnetic and thermal simulations that highlight the technology's efficiency and potential areas for optimization in food safety and quality enhancement.

References

[1]. https://www.ntia.doc.gov/page/2011/manual-regulations-and-procedures-federal-radio-frequency-management-redbook

[2]. http://hfwoodmachinery.com/2-high-frequency-edge-gluer/187641/

[3]. Huang, Zhi, Francesco Marra, and Shaojin Wang. "A novel strategy for improving radio frequency heating uniformity of dry food products using computational modeling." Innovative Food Science & Emerging Technologies 34 (2016): 100-111.