The study of traction motors has recently become a fascinating topic due to the critical role they play in electric vehicles. Among the traction motors, the interior permanent magnet (IPM) synchronous machines are the most widely used in commercial electric powertrains due to their high efficiency and power density. Among the commercial electric powertrains that use the synchronous IPM machine, Nissan LEAF, introduced in 2010, is one of the earliest and most popular electric cars. Despite the stiff competition from Tesla and Toyota, the LEAF remains very viable. Of course, many reasons make an electric car successful and competitive but the electric motor is probably the most important component of an electric car. It is, therefore, intriguing to simulate and study the LEAF motor.

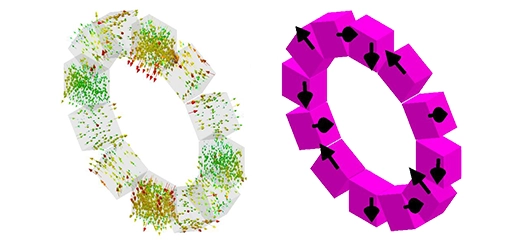

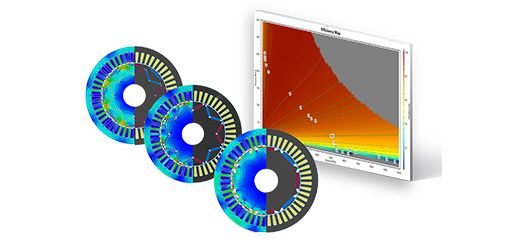

In this webinar, we will dive deep into the LEAF motor design. We will use our motor and electromagnetic simulation software tools, MotorWizard and EMWorks2D to assist us in our dive. The LEAF IPM rotor has three different topologies, the single V-shape, Flat-shape, and Delta-shape. We shall study each topology and show its performance results, including electromagnetic torque, power, speed, efficiency map, back EMF, and flux distribution; a comparison of the peak power realized by each topology will also be discussed. In addition, we will discuss the losses and how they are related to the temperature rise in the machine.