How to Efficiently Design NDT Equipment Using Electromagnetic Simulation?

Non-destructive testing (NDT) is nowadays widely used for many applications in aerospace, petroleum, civil engineering, and many more manufacturing and service environments to ensure safety and production quality. NDT is divided into various methods of non-destructive testing, each based on a particular scientific principle for example electromagnetic testing.

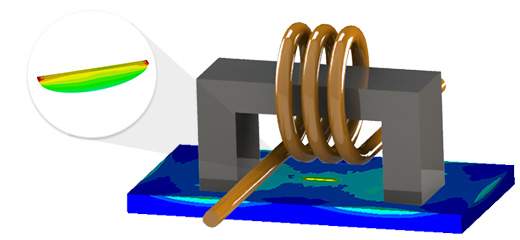

Electromagnetic inspection is the non-destructive testing method that includes magnetic fields and electric currents. It allows to measure a response caused by a defect on a non-ferrous metallic or ferromagnetic object or investigate its properties. Electromagnetic testing involves various types of methods such as eddy current testing, alternating current field measurements, magnetic flux leakage, pulsed eddy current and eddy current thermography, etc.

The working principles of these methods require one or more physics like static and dynamic magnetic fields, motion, thermal quantities, etc. Hence, CAD design and simulation tools constitute a great solution that helps engineers and designers to better understand the operation of their NDT sensors and improve them.

EMWorks electromagnetic simulation software helps you inspect and explore results of magnetic fields, eddy currents, back emf, current, resistance, and inductance of the sensing coil along with the temperature of an NDT device.

Join us in this webinar to learn more about different NDT technologies and how EMWorks software can help you characterize the performance of your NDT sensor